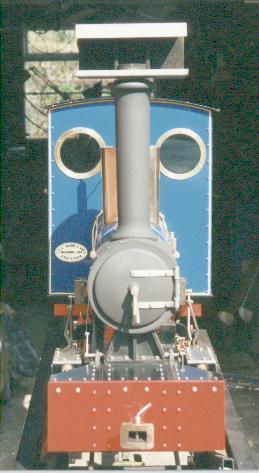

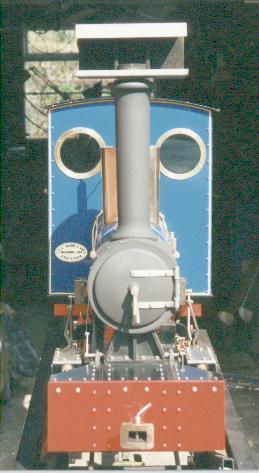

UNDER ARREST! - By Graham Walker

This item explains the peculiar structure sprouting from “Katie’s” chimney in the photographs above! Having experienced two rather nasty burns on small children, I decided it was time to do something about it! My first “quick-fix” spark arrestor was just a simple square umbrella type affair, suspended about 5” above the chimney (above). This seemed to work quite well, but all the hot ashes and cinders were directed downwards onto the smokebox and the motion making a terrible mess. I therefore developed a Mark II. This was similar to Mark I but a little longer and incorporated a catchment tray thus overcoming the dirty motion problem and I think it was probably about 90% effective. The only time it was suspect was when working hard at ‘high speed’ climbing the long bank away from the tunnel. So I embarked on a Mark III design made from 16 s.w.g. stainless steel. This was simply Mark II with a back-skirt fitted. This had the desired effect and I think it worked at around 99% efficiency. The only real problem was that the contraption was anything but railway-like in appearance. Certain of our members at Wortley Top Forge MES had been heard referring to it as a “kipper smoker” or a “fish fryer”....... and probably worse when I was out of earshot! During the winter, I tried to come up with a spark arrestor design that was more befitting a railway locomotive when lo and behold, a two-page spread appeared in The Model Engineer (Vol. 186 Feb 2001 page 122) by a Mr Alan Bibby.

The design is a stainless steel gauze about 16 mesh. This is formed into a cylinder and fits on to collar just under the blast nozzle and finished at the petticoat throat (see below). So I am now back to a Mark I smokebox type spark arrestor and it is now awaiting trials. It will be interesting to see how it performs!